I. Introduction: The Unseen Precision of Winding Technology

In the intricate tapestry of modern manufacturing, where precision, efficiency, and reliability are paramount, certain technologies operate behind the scenes, yet are absolutely indispensable. Among these unsung heroes are winding machines – sophisticated devices that meticulously wrap wire, fiber, or other materials around a core or former to create coils, components, and structures essential to a vast array of industries. From the microscopic coils in medical implants to the robust windings of aerospace components and the critical elements within energy storage systems, winding technology is the silent force enabling technological advancement and innovation across the globe.

At its core, a winding machine performs a seemingly simple task: arranging conductive or structural materials in a precise pattern. However, the complexity lies in the exactitude required for these applications. The performance, durability, and efficiency of the final product – be it an electric motor, a transformer, a sensor, or a composite structure – are directly dependent on the quality and precision of its winding. Any deviation, however slight, can lead to inefficiencies, premature failure, or compromised functionality, underscoring the critical role these machines play in ensuring the integrity and performance of countless modern devices.

This article will delve into the fascinating world of winding machines, exploring their fundamental principles, the advanced techniques that define their capabilities, and their diverse applications across critical sectors such as aerospace, medical, and energy storage. We will trace the evolution of this technology, from its humble manual beginnings to the highly automated, intelligent systems of today, and peer into the future trends that promise even greater precision and efficiency. Furthermore, we will highlight Guangri Electronic Machinery Co., Ltd., a prominent Chinese manufacturer, as a leading example of a company at the forefront of this specialized field, demonstrating how their expertise in precision winding machines contributes to the technological backbone of various industries. Join us as we unravel the complexities and appreciate the unseen precision that winding technology brings to our modern world.

II. Advanced Winding Techniques: Crafting Performance

The art and science of winding have evolved significantly, moving beyond simple coil formation to encompass a range of advanced techniques designed to optimize performance, enhance durability, and meet the stringent demands of modern applications. These techniques are crucial for achieving the precise geometries, insulation properties, and electrical characteristics required in high-performance components. The choice of winding technique directly impacts a product’s efficiency, power density, and lifespan.

Flyer Winding: High-Speed Automation for Uniformity

Flyer winding is a high-speed, automated process widely used for producing coils with uniform wire placement. In this technique, the wire is fed from a stationary supply through a rotating flyer arm that guides it onto a rotating bobbin or core. The continuous rotation of the flyer ensures consistent tension and precise layering of the wire, leading to highly uniform and compact coils. This method is particularly advantageous for mass production due to its speed and efficiency, significantly reducing manufacturing time while maintaining high quality. The uniformity achieved through flyer winding is critical for applications where consistent electrical properties and minimal variations between coils are essential, such as in transformers, inductors, and small electric motors. Its automated nature also minimizes human error, contributing to greater reliability and reproducibility in the manufacturing process.

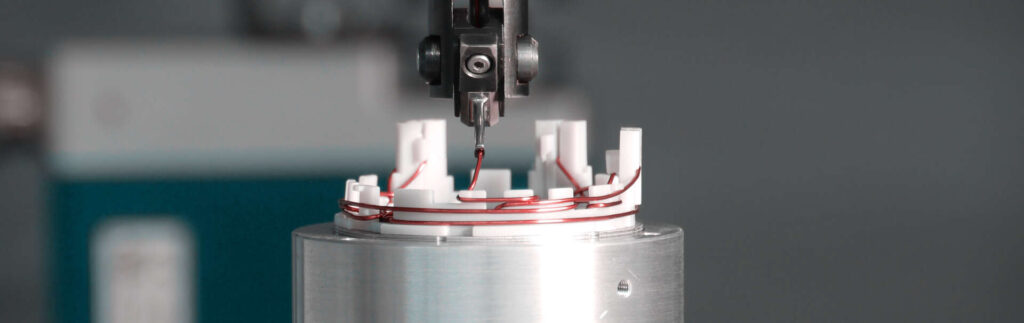

Needle Winding: Precision for Multi-Layered Structures

Needle winding is a specialized technique employed for creating precise, multi-layered winding structures, especially in applications requiring high slot fill factors and complex coil geometries. Unlike flyer winding, where the bobbin rotates, in needle winding, a needle-like nozzle moves through the stator slots, laying the wire directly into the desired position. This method offers exceptional control over wire placement, allowing for very tight and accurate layering, which is crucial for optimizing the magnetic properties and thermal management of the coil. Needle winding is particularly well-suited for winding stators of electric motors, where precise placement of each turn is vital for achieving optimal performance and efficiency. Its ability to handle intricate designs and achieve high slot fill makes it indispensable for compact and high-power density motors used in various advanced applications.

Resin-Impregnated Windings: Enhancing Durability and Performance

Resin impregnation is a post-winding process that significantly enhances the durability, electrical insulation, and thermal performance of wound components. After the wire is wound onto the core, the entire assembly is immersed in a specialized resin (e.g., epoxy, polyester, or silicone-based resins) under vacuum. The vacuum ensures that the resin penetrates all voids and air pockets within the winding, completely encapsulating the wires and insulation. Once cured, the resin forms a solid, protective matrix that offers several critical benefits: it improves dielectric strength, protecting against electrical breakdown; it enhances mechanical stability, preventing wire movement and vibration; it provides superior protection against moisture, chemicals, and contaminants; and it improves heat dissipation by filling air gaps, thereby extending the motor’s lifespan and preventing overheating. This technique is widely used in motors and transformers operating in harsh environments or requiring high reliability, such as those found in industrial machinery, automotive systems, and aerospace applications.

Hairpin Winding: A Modern Approach for Electric Vehicle Motors

Hairpin winding, also known as bar winding, is an advanced technique gaining significant traction, particularly in the manufacturing of electric vehicle (EV) motors and other high-performance electric machines. This method involves forming copper conductors into a hairpin shape, which are then inserted into the stator slots and welded together at the ends. Unlike traditional round wire windings, hairpin conductors have a larger cross-sectional area, which allows for higher current density and improved thermal management. This leads to increased power density, higher efficiency, and better heat dissipation in the motor. The robust nature of hairpin windings also contributes to enhanced durability and vibration resistance. While the manufacturing process can be more complex, the performance benefits, especially for high-power and high-torque applications like EV powertrains, make hairpin winding a preferred choice for next-generation electric motors.

Foil Winding: Advantages in Power Electronics

Foil winding is a specialized technique that utilizes thin strips of conductive foil (typically copper or aluminum) instead of round wire. This method is particularly advantageous in power electronics applications, such as high-frequency transformers and inductors, where low voltage and high current are prevalent. The flat geometry of the foil conductors offers several benefits: it reduces the proximity effect, leading to lower AC losses at high frequencies; it provides superior heat dissipation due to a larger surface area; and it allows for more compact designs with higher power density. Foil windings are also inherently more robust mechanically and offer better insulation properties when interleaved with insulating materials. This technique is crucial for optimizing the performance and efficiency of power conversion systems, contributing to smaller, lighter, and more efficient electronic devices across various industries.

III. Industry-Specific Applications of Winding Machines

Winding machines are not confined to a single industry; their precision and versatility make them indispensable across a multitude of sectors, each with its unique demands and applications. From the cutting-edge requirements of aerospace to the life-saving innovations in medical devices and the burgeoning field of energy storage, winding technology forms the backbone of critical components that drive progress and enable new functionalities. The ability of these machines to produce highly specialized coils and structures is what makes them so vital to modern technological ecosystems.

Aerospace: Precision for Critical Flight and Space Systems

In the aerospace industry, where safety, reliability, and performance are paramount, winding machines play a crucial role in manufacturing components for aircraft, satellites, and defense systems. The extreme conditions encountered in aerospace applications—ranging from vast temperature fluctuations to intense vibrations and radiation—demand components that are not only highly efficient but also incredibly robust and durable. Winding machines are used to produce precision coils for actuators, sensors, navigation systems, and communication equipment. For instance, the electromagnetic coils in flight control systems must operate flawlessly under immense stress, and their integrity is directly dependent on the precise winding of their internal components. Similarly, in satellite technology, the miniaturization and reliability of wound components are critical for mission success. The ability of winding machines to achieve ultra-fine wire winding and complex geometries ensures that these critical aerospace components meet the rigorous standards required for safe and effective operation in the most demanding environments.

Medical Devices: Miniaturization and Reliability for Healthcare Innovation

The medical device industry relies heavily on precision manufacturing to create instruments and implants that are often microscopic yet perform life-critical functions. Winding machines are essential for producing a wide array of components, including coils for diagnostic equipment like Magnetic Resonance Imaging (MRI) machines, and intricate windings for surgical tools, catheters, and implantable devices. For example, the tiny coils within neurostimulators or pacemakers require extreme precision to deliver therapeutic electrical pulses. Similarly, the flexible, multi-lumen catheters used in minimally invasive surgery often incorporate fine wire windings for steering mechanisms or sensor integration. The demand for miniaturization, biocompatibility, and unwavering reliability in medical applications means that winding machines must deliver exceptional accuracy and consistency, often working with incredibly fine wires and specialized materials. This precision ensures that medical devices function safely and effectively, contributing to improved patient outcomes and advancements in healthcare.

Energy Storage: Powering the Future with Efficient Components

As the world transitions towards sustainable energy solutions, the importance of efficient energy storage systems has grown exponentially. Winding machines are at the forefront of manufacturing critical components for batteries, supercapacitors, and flywheels, which are integral to electric vehicles (EVs), renewable energy grids, and portable electronic devices. In EVs, for instance, the motor windings are fundamental to the vehicle’s performance, efficiency, and range. Precision winding ensures optimal energy conversion and minimal losses, directly impacting the vehicle’s power output and battery life. For grid-scale energy storage, winding machines produce the inductors and transformers necessary for power conversion and management, ensuring stable and reliable energy flow. The ability to create high-density, low-loss windings is crucial for maximizing the efficiency and lifespan of these energy storage solutions, making winding technology a key enabler for a greener, more electrified future.

Automotive: Driving Efficiency and Performance in Vehicles

Beyond electric vehicles, winding machines are integral to the broader automotive industry, producing a wide range of components that enhance vehicle efficiency, safety, and performance. This includes windings for various types of motors (e.g., for power steering, window regulators, and cooling fans), sensors, and other electronic components. The trend towards more electrified and autonomous vehicles further increases the demand for precise and durable wound components. For example, the coils in anti-lock braking systems (ABS) or electronic stability control (ESC) sensors require meticulous winding to ensure accurate data collection and rapid response times. The harsh automotive environment, characterized by vibrations, temperature extremes, and exposure to fluids, necessitates highly robust and reliable windings, which advanced winding machines are designed to produce. This ensures that modern vehicles are not only more efficient but also safer and more technologically advanced.

Consumer Electronics: Enabling Everyday Technology

While often unseen, wound components are ubiquitous in the consumer electronics we use daily. Winding machines produce the coils for speakers, headphones, wireless charging pads, and various small motors found in household appliances like washing machines, refrigerators, and fans. The miniaturization trend in consumer electronics demands increasingly compact and efficient wound components. For instance, the tiny coils in smartphones that enable wireless charging or haptic feedback require incredibly precise winding techniques. Similarly, the transformers and inductors in power adapters and chargers rely on accurate windings for efficient power conversion. The sheer volume of consumer electronics produced globally means that winding machines in this sector must be highly automated, fast, and capable of maintaining consistent quality at scale, ensuring that our everyday devices are both functional and reliable.

IV. The Evolution of Winding Technology: From Manual to Automated Precision

The history of winding technology is a testament to humanity’s relentless pursuit of efficiency, precision, and automation. What began as a laborious manual process has transformed into a highly sophisticated, digitally controlled operation, mirroring the broader trajectory of industrial development. This evolution has been driven by the increasing demand for more complex, reliable, and miniaturized electrical and mechanical components across diverse industries.

Early Beginnings: The Era of Manual Winding

In its earliest forms, coil winding was a purely manual endeavor. Craftsmen meticulously wrapped wires around bobbins or cores by hand, relying on their skill and dexterity to achieve the desired number of turns and uniform layering. This method, while capable of producing functional coils, was inherently slow, prone to inconsistencies, and highly dependent on the individual operator’s expertise. As the demand for electrical components grew with the advent of electricity and early electrical machines in the late 19th and early 20th centuries, the limitations of manual winding became increasingly apparent. The need for faster, more consistent production spurred the development of rudimentary mechanical aids.

Industrial Revolution Impact: The Rise of Mechanical Winders

The Industrial Revolution brought about significant advancements in machinery, and winding technology was no exception. Simple mechanical winding machines emerged, utilizing gears, belts, and levers to automate the winding process to a certain extent. These early machines, while still requiring significant human intervention for setup and monitoring, dramatically increased production speeds and improved consistency compared to purely manual methods. They laid the groundwork for more complex automation by standardizing the winding motion and tension control. This period saw the widespread adoption of winding machines in the nascent electrical industry for producing coils for motors, generators, and transformers, marking a crucial step towards mass production of electrical components.

Automation Era: The Advent of CNC and Programmable Machines

The mid-20th century ushered in the true automation era for winding technology with the introduction of numerical control (NC) and later, computer numerical control (CNC) systems. These programmable machines revolutionized the industry by allowing for precise, repeatable, and complex winding patterns to be executed with minimal human oversight. CNC winding machines could control not only the speed and tension of the wire but also the exact position of the winding head, enabling the creation of intricate coil geometries and multi-layered windings with unprecedented accuracy. This advancement was critical for the development of smaller, more efficient, and higher-performance electrical components required by the burgeoning electronics industry. The ability to program complex winding sequences opened up new possibilities for product design and manufacturing efficiency.

Modern Advancements: Robotics, AI, and Advanced Materials

Today, winding technology continues its rapid evolution, integrating cutting-edge advancements such as robotics, artificial intelligence (AI), and the use of advanced materials. Robotic arms are increasingly being employed in winding processes, offering unparalleled flexibility and precision for handling delicate wires and complex coil forms. AI and machine learning algorithms are being used to optimize winding parameters, predict potential defects, and even design more efficient coil geometries. This allows for real-time adjustments and continuous improvement in the manufacturing process. Furthermore, the development of new conductive and insulating materials, such as high-temperature superconductors and advanced polymers, is pushing the boundaries of what wound components can achieve in terms of power density, thermal management, and durability. These modern advancements are enabling the creation of components for next-generation technologies, from compact electric vehicle motors to high-efficiency renewable energy systems.

Future Trends: Miniaturization, Higher Efficiency, and Smart Winding Solutions

Looking ahead, the future of winding technology is poised for even greater innovation. Key trends include continued miniaturization, driven by the demand for smaller and more powerful electronic devices. This will necessitate even finer wire winding capabilities and more precise control systems. The pursuit of higher energy efficiency will lead to further optimization of winding patterns and the development of new materials that minimize energy losses. The concept of

smart winding solutions, incorporating sensors and real-time data analysis, will enable predictive maintenance and adaptive manufacturing processes. The integration of additive manufacturing (3D printing) for creating complex coil forms and embedded components is also on the horizon, promising revolutionary changes in how wound products are designed and produced. These future trends underscore the dynamic nature of winding technology and its enduring importance in shaping the technological landscape of tomorrow.

V. Guangri Electronic Machinery Co., Ltd.: A Leader in Winding Solutions

In the specialized and demanding field of precision winding technology, Guangri Electronic Machinery Co., Ltd. stands as a distinguished Chinese manufacturer, renowned for its expertise in producing high-quality winding machines. With a strong focus on innovation and precision, Guangri has established itself as a critical supplier for industries where the integrity and performance of wound components are paramount. Their commitment to advanced manufacturing techniques and customer-centric solutions has positioned them as a leader in the global market for winding equipment.

Company Overview: A Legacy of Precision Manufacturing

Guangri Electronic Machinery Co., Ltd. is a prominent Chinese manufacturer specializing in the design, development, and production of precision winding machines. Located in a region known for its industrial prowess, Guangri has leveraged its strategic position and extensive experience to become a key player in the winding technology sector. The company’s mission revolves around providing cutting-edge winding solutions that meet the evolving needs of various high-tech industries, ensuring optimal performance and reliability of the components produced by their machines. Their long-standing presence in the market is a testament to their consistent quality and adaptability to technological advancements.

Expertise Across Diverse Industries: Tailored Winding Solutions

What sets Guangri apart is its profound understanding of the specific requirements of different industries. They develop and manufacture winding machines tailored for a wide array of applications, including:

•Aerospace: Producing machines capable of handling the ultra-fine wires and complex geometries required for aerospace components, such as sensors, actuators, and control systems, where precision and reliability are non-negotiable.

•Medical: Designing winding solutions for the delicate and miniaturized coils found in medical devices, including MRI machines, pacemakers, and surgical instruments, where accuracy and biocompatibility are paramount.

•Energy Storage: Manufacturing machines essential for the production of components for advanced batteries, supercapacitors, and electric vehicle motors, contributing to the efficiency and longevity of modern energy solutions.

•Automotive: Providing winding equipment for various automotive electrical components, from traditional motor windings to advanced solutions for electric and hybrid vehicles.

•Consumer Electronics: Developing high-speed, high-precision winding machines for the mass production of coils used in everyday electronic devices, ensuring consistency and efficiency.

This broad industrial reach underscores Guangri’s versatility and their ability to adapt their technology to meet the stringent demands of highly specialized sectors.

Product Range: Comprehensive Winding Machine Solutions

Guangri Electronic Machinery Co., Ltd. offers a comprehensive range of winding machines, each designed to address specific winding challenges and applications. While their expertise spans various types, a core focus includes:

•Motor Winding Machines: Specializing in machines for winding stators and rotors of various electric motors, ensuring high efficiency, optimal torque, and extended lifespan. These machines incorporate advanced techniques like needle winding and flyer winding to achieve superior results.

•Coil Winding Machines: Producing general-purpose coil winding machines for inductors, transformers, and other electromagnetic components, catering to a wide spectrum of sizes and complexities.

•Precision Winding Equipment: Developing highly specialized machines for micro-coils and fine wire applications, critical for miniaturized components in medical and aerospace fields.

Their product portfolio reflects a commitment to providing solutions that are not only technologically advanced but also robust, reliable, and user-friendly.

Commitment to Quality and Innovation: Driving the Future of Winding

Guangri’s success is rooted in its unwavering commitment to quality and continuous innovation. They invest significantly in research and development to stay at the forefront of winding technology, incorporating the latest advancements in automation, robotics, and material science into their machines. Their manufacturing processes adhere to stringent quality control standards, ensuring that every machine leaving their facility delivers exceptional performance and durability. By focusing on precision engineering and leveraging their deep industry knowledge, Guangri consistently pushes the boundaries of what is possible in winding technology, contributing significantly to the efficiency and advancement of the industries they serve. Their dedication to innovation ensures that their clients always have access to the most advanced and reliable winding solutions available in the market.

VI. Conclusion: Winding Towards a Smarter Future

The journey through the world of winding machines reveals a technology that, while often unseen, is profoundly impactful. From the foundational principles of electromagnetic induction to the sophisticated advancements in automated precision, winding technology has consistently adapted and evolved to meet the ever-increasing demands of modern industry. Its critical role in crafting the essential components of electric motors, transformers, sensors, and composite structures underscores its indispensable nature in our technologically driven world.

The precision and versatility of winding machines are what truly set them apart. They enable the miniaturization of medical devices, the robust performance of aerospace components, and the efficient energy conversion within advanced energy storage systems. The continuous innovation in winding techniques, such as hairpin and foil winding, alongside the integration of robotics and AI, signifies a relentless pursuit of higher efficiency, greater power density, and enhanced reliability across all applications. This evolution is not merely about mechanical improvement; it’s about enabling breakthroughs in diverse fields, pushing the boundaries of what is technologically possible.

Companies like Guangri Electronic Machinery Co., Ltd. stand as pillars in this specialized domain, embodying the expertise and commitment to quality that are vital for the industry’s progression. Their dedication to providing tailored winding solutions across aerospace, medical, energy storage, and other critical sectors highlights the specialized knowledge and advanced manufacturing capabilities required to meet stringent industry standards. By focusing on precision, innovation, and comprehensive product ranges, manufacturers like Guangri are not just building machines; they are building the future, one meticulously wound component at a time.

As we look ahead, the trajectory of winding technology points towards even greater sophistication, driven by the demands for smarter, more efficient, and increasingly compact solutions. The ongoing research into new materials, advanced control systems, and integrated manufacturing processes promises to further revolutionize how power is generated, stored, and utilized. The unseen precision of winding machines will continue to be a cornerstone of technological advancement, silently powering the innovations that shape our world and propel us towards a smarter, more connected, and more efficient future.